Lightweight, wearable nuts.

POLAK, the next generation batting material.

Sustainable

No need for pesticides and deforestation

Hollow structure with high heat retention

Made of Kapok, one-eighth as light as cotton.

We live in a time, which everyone is seeking to contribute to a sustainable society and new lifestyles.

POLAK has been created from a new material produced from the nuts of the natural Kapok tree.

Compared to the fibers derived from petroleum or animals, POLAK is less harmful to the environment and does not require large-scale cultivation or deforestation. Also, expected to contribute to a recycling-based society.

Raw material of POLAK

What’s Kapok?

Kapok (Ceiba Petandra) is a natural plant which grow mainly in Java. Kapok Fibers are collected from the fruit of a tall tree 10 to 30 meters high. Kapok fibers are 18 to 27 mm in length, approximately 0.02mm in diameter, and has a straw like structure.

Kapok fibers are lightweight, have excellent heat retention and waterproofing properties, most of kapok fibers have been used for life saving equipment and bed batting, but due to the difficulty of spinning, its market share is smaller than the other fibers.

This led to the creation of POLAK, a 100% plant-derived, functional batting made from kapok fibers that are made into a cotton sheet by using Toyoshima’s technology.

Reasons for lightness and warmness

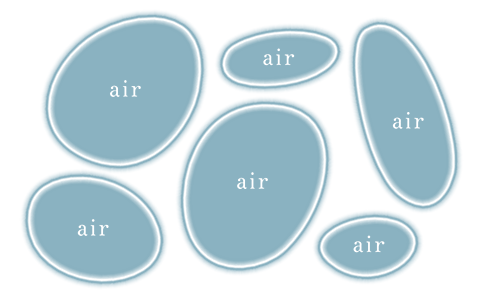

Hollow Structure

Hollow ratio of Kapok fibers are 70~80%. It possesses the highest hollow ratio of any natural fiber, so it’s one-eighth as light as cotton.

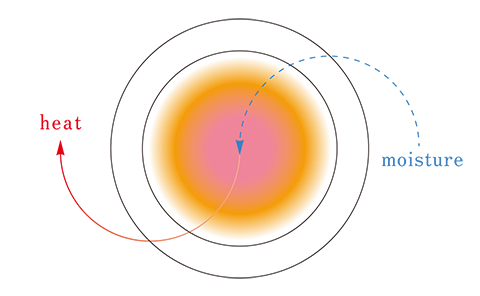

Hygroscopicity

The hollow part of the kapok fibers absorb the moisture emitted from the body, and heat is generated using the condensation heat which is generated when the water vapor turns into water.

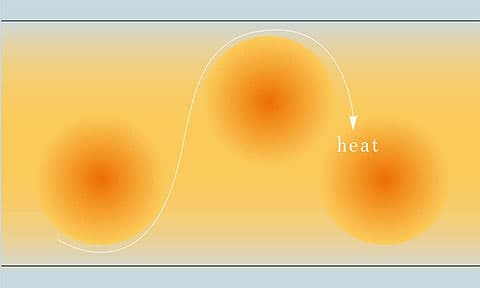

Heat retention

The air-packed interior of the sheet provides heat retention due to its low heat conductivity.

Values and Technologies

Leading to a sustainable future.

POLAK is manufactured by mixing kapok fibers with PLA, a biomass raw material made from corn and sugarcane starch, also mixing with marine degradable polymers. In addition, manufacturing products that reduces environmental impact as much as possible, we are working to develop technology while creating new values, such as clear traceability and building a supply chain that does not send waste products out into the world.

Similarities between

Polar Bears and Kapok

The hair of the Polar Bears living in the Arctic, and the fiber from the Kapok nuts growing naturally in the tropics.Although these two live in opposite environments, but they both possess a hollow structure, lightweight structure, and high heat retention structure. Manufacturing POLAK, that utilize native materials as new materials, supports the preservation of a natural environment where endangered polar bears can live safely.

Becomes a style.

POLAK is not only functional, it also creates a lifestyle for those who use it. We hope that POLAK will become a new option for people today who are concerned about environmental conservation and creating a risk-free future.